Dimensional Research recently published a study regarding the challenges of new product introduction (NPI) in the post-coronavirus pandemic landscape. The “2020 Trends in Electronics Sourcing” survey states 53 percent of powered device industry product launches have been put off or canceled due to the global health crisis. The group noted that a prime contributing factor to this is inter-organizational dysfunction.

Luckily, firms can address this serious issue by one simple solution: foster collaboration between engineering and sourcing teams.

Main Causes of NPI Delays and Cancellations

According to the market research firm, the leading cause of delayed or scrapped NPIs is sourcing problems. One major supply chain issue that has arisen in the post-pandemic era is increased component cost. To slow the spread of the outbreak, regional governments enacted travel restrictions, which constrained logistics providers’ shipping capacity. That change meant corporations had to pay more to move smaller amounts of freight at a considerably slower rate.

Dimensional Research also discovered the pandemic undercut NPIs by making crucial components harder to procure. With major production hubs shuttered because of the viral outbreak, orders went undelivered. Even after officials lifted shutdown orders in many countries, manufacturers struggled to return to full capacity due to worker shortages.

Pandemic related material cost increases and inventory scarcity are factors corporations cannot control. But companies can decide how they react to adversity, and unfortunately, many are not setting themselves up for success.

The electronics sourcing study states 31 percent of respondents made new vendor arrangements without adequately vetting their new partners. Unfortunately, that crunch related lowering of standards resulted in higher levels of supply errors and drops in materials quality. Manufacturers that sought out quick fixes ended up risking permanent reputational damage.

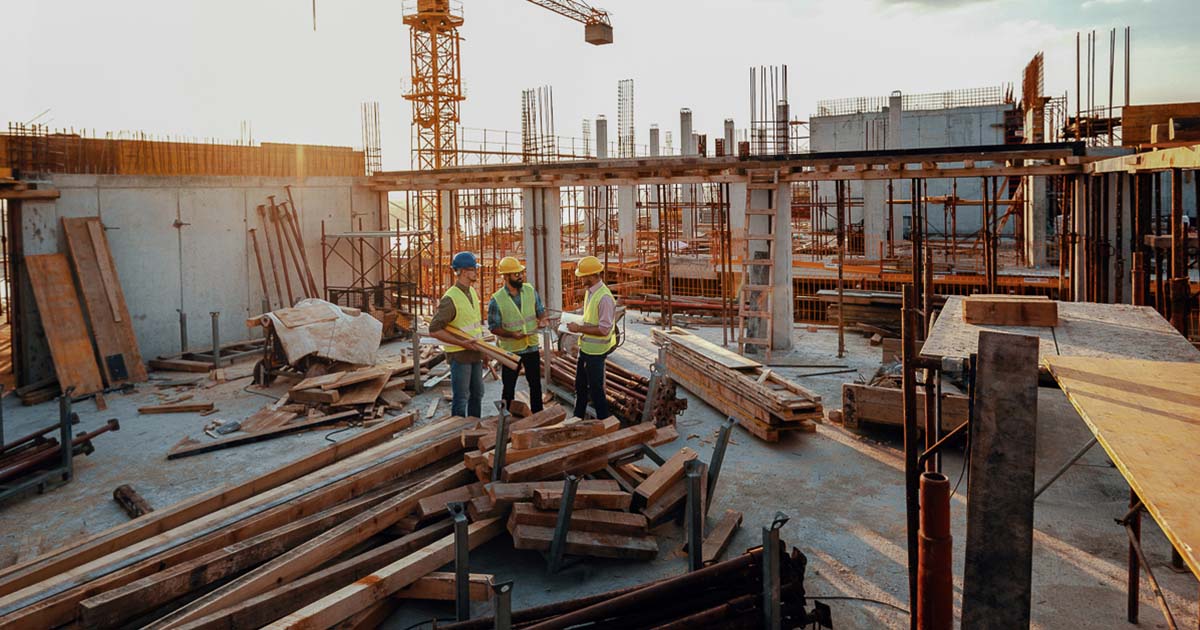

Engineering and Sourcing Collaboration as an NPI Solution

Dimensional Research’s survey uncovered the many problems the coronavirus has introduced into the NPI process, but it also points to a significant mitigation solution. Engineers and sourcing teams can make product launches go much more smoothly by working in tandem.

Lacking an adequate understanding of market conditions, designers can create their newest offerings using difficult or impossible to source components. Engineers also unintentionally make NPIs more expensive by not factoring procurement lead times into their device architecture. During growth periods, those kinds of communication breakdowns can be damaging, but in times of economic contraction, they can be devastating.

Manufacturers can prevent this problem by looping in procurement leads throughout product development. This way, procurement agents can make critical sourcing adjustments to maximize their cost-effectiveness and deliverability.

Company departments might initially struggle with finding efficient workflows when partnering up for the first time. However, they can make transitions more seamless by providing teams with first-rate enterprise resource planning tools and product lifecycle management systems. Dimensional Research’s findings are clear; firms can optimize NPI outcomes by prompting cooperation between their design and procurement specialists.